不锈钢网链隧道炉

塑胶件隧道炉

丝印隧道炉

隧道炉

Shenzhen Anfeng Tai high temperature tunnel furnace is compatible with catalytic degreasing, metallurgical degreasing, vacuum degreasing, drying curing. Widely used in electronics, telecommunications, electroplating, plastics, metal, chemical, silk screen, spray, glass, touch screen etc for precision baking, drying, preheating, stereotypes processing industries. Size specifications, temperature, material, style, etc. can be customized according to production requirements.

Tunnel furnace types:

- 1, cold rolled steel, galvanized sheet, all stainless steel, color steel plate structure;

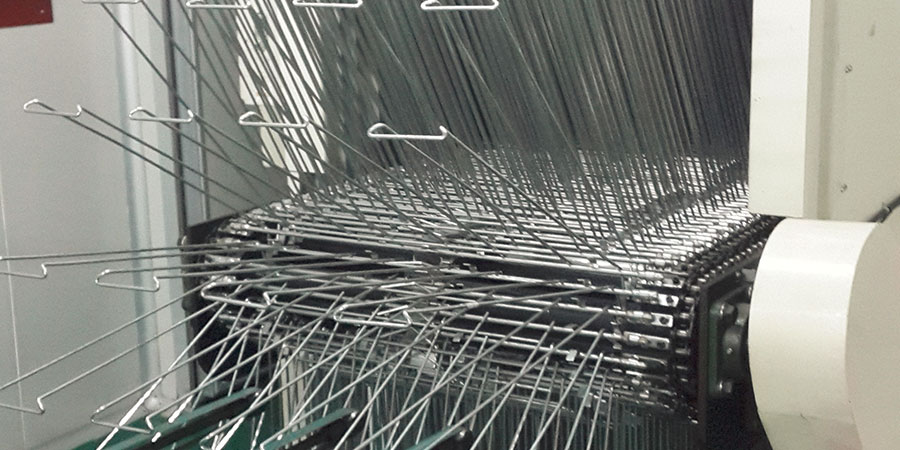

- 2, belt conveyor, stainless steel mesh belt conveyor, chain plate conveyor, Teflon belt conveyor;

- 3, low-temperature plastic, metal temperature, Teflon high temperature;

- 4, style: spray drying, spray drying, silk screen drying, food drying, etc .;

- 5, heating methods: far infrared, gas burner head, gas Ran burning machine, diesel-burning machine, firewood (coal) indirect heating;

Stainless steel mesh belt tunnel furnace principle: The main principle is to evenly tiles in the mesh belt, mesh belt with 12-60 mesh steel mesh belt, driven by the transmission device in the dryer to move back and forth between the hot air flow through the material But the water vapor from the drainage holes in the discharge, so as to achieve the purpose of drying, box length from the combination of the standard section.

Mesh belt tunnel furnace features: small footprint, low investment, high efficiency, large output, evaporation intensity, standardized production, according to the output increase the number of segments.

Tunnel furnace technical parameters:

- 1, high-temperature tunnel furnace line body size required to set up, import and export regulation plate

- 2, room temperature to 800 degrees adjustable, can be constant temperature, each section of independent control

- 3, the configuration of two high-temperature transport wind motor, hot air circulation, internal temperature uniformity, fast heating, baking objects as a whole heat evenly

- 4, thermal insulation layer of high-quality silicate cotton, thermal insulation effect

- 5, stainless steel mesh belt transmission, high temperature, clean, easy to clean

- 6, with a conveyor belt tension adjustment device

- 7, imported frequency converter, conveyor belt adjustable speed, smooth operation

- 8, intelligent SSR solid state relay output, precise control of temperature accuracy

- 9, double over-temperature protection, electrical control safe and reliable

- 10, intelligent temperature controller, PID automatic calculation, LED display; tunnel furnace body shell temperature is low, the indoor temperature and humidity, energy saving, safety performance.

Our company specializes in the production of tunnel drying furnace, tunnel furnace, drying line, clean tunnel furnace, clean drying line, tunnel drying line, IR tunnel furnace, hot air tunnel furnace, touch screen tunnel furnace, Tunnel tunnel furnace, the industry tunnel furnace, the tunnel industry furnace, the tunnel industry, the tunnel industry, the tunnel industry, the tunnel industry, the tunnel industry, the tunnel industry, Foamed material tunnel furnace.