Process flow (for reference only, customizable)

Load → manual dust removal → automatic dust removal → preheating → spray primer → leveling → ir leveling → cooling → topcoat → ir leveling → uv curing → cooling → Unload

Overview of workflow

The entire coating area (including load and unload area) are closed dust free environment, staff access to this area must go through air shower, the workshop is configured with fresh air supply and efficient exhaust device to ensure that its air cleanliness Not less than 100000 class. Loading area is arranged with assembly table, manual way to assemble the workpiece then manually electrostatic de-dust, products are sent to spray area by chain conveyor. The workpiece will be handled through automatic de-dust and preheating then automatic painting.

Spray booth fresh air supply is generated through high-performance filter then sent to spray area; cleanliness is controlled within 10000 class. Waste gas exhausting is handled by exhausting fan on spray booth to send to the roof gas treatment unit. Before emit to atmosphere, more than 80% of waste paint mist has been filtered in spray booth water curtain. After the final gas treatment, it's safe, non-toxic, and no secondary pollution.

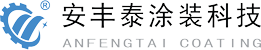

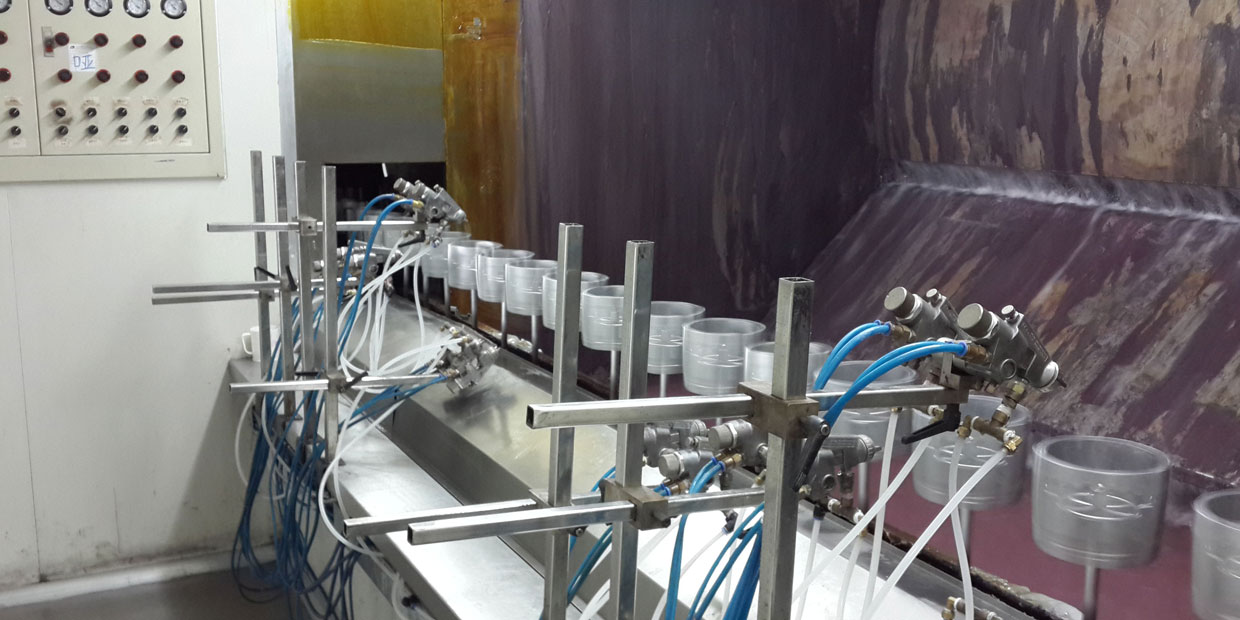

Coating method can be fixed spray gun, reciprocating machine online tracking and spraying robot with special spray gun, the paint flow and atomization is stable and reliable, to ensure the quality of the spray. In order to obtain a good uniform coating of all parts, the conveyor chain in the spraying station are equipped with forward and reverse rotation two devices (80 ~ 200 r / min, frequency control), and guns match. When the photoelectric sensor to fixture to hang a workpiece, the rotation device starts, and then set the spray conditions to start automatic spraying. This kind of workpieces can be sprayed in rotation. As long as the rotational speed and spraying conditions are properly set and matched, not only the obtained coating film is extremely uniform, the quality is stable and excellent, and the coating is saved very much.

The sprayed workpiece after spraying then enters the leveling section. The leveling section is provided with an air supply device and an exhaust device to ensure that the paint concentration in the leveling room does not exceed the explosion limit and ensure safety.

The flattened workpiece enters the drying oven and is cured by electrical heating. Curing furnace heating using ceramic or stainless steel heating pipe hot air circulation. Furnace appearance is beautiful, strong and durable. All use of stainless steel liner, not rust, suitable for regular maintenance and cleaning. Because the heating pipe is evenly distributed, pid proportional regulation, stove temperature stable, uniform, and in the control panel with automatic display and record the furnace temperature measuring instrument, truthful records, visual display, easy observation and control. Baking the workpiece baked into the fresh air cooling section.

Within Uv machine, operator can adjustt the distance between workpiece and lamp to ensure curing time and energy are just right. At the same time, conveyor chain on UV curing station is also equipped with rotation device to ensure uniform irradiation, uniform curing.